R&D

In Teinco we have been committed to innovation since our creation, 35 years ago, and we have strengthened our R&D department with the aim of improving and optimizing the automation of our customers' factories. This commitment has made us a reference as a technological leader and with a wide experience of our technical team in the food sector.

PROCESS TECHNOLOGIES

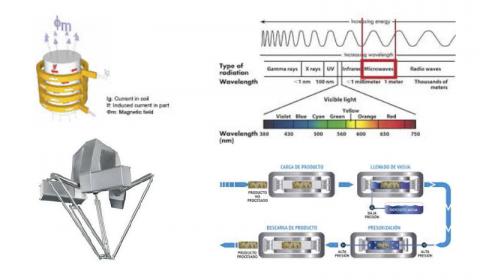

We have a wide experience in the application of new process technologies:

- Microwaves,

- high pressures,

- ultrasound,

- induction,

- ohmic heating,

- thermal sterilization and pasteurization,

- automation and robotization.

PATENTS

PATENTS

Patent No. 201530815 (6) in Spain.

Title "Procedure and system for food sterilization control in a retort".

Applicant/s: TEINCO, INDUSTRIAS FRIGORÍFICAS DEL LOURO S.A.View complete info

Caride Castro, Amado; Meniño Cotón, José Luís; Moreno Carbajo, Vanesa and others.

Title: Procedure and apparatus for continuous cleaning of cooked tuna loins.

Identification number: 201330346. Country: Spain. ANFACO-CECOPESCA See complete info

Caride Castro, Amado; Meniño Cotón, José Luís; Moreno Carbajo, Vanesa and others.

Title: Procedure and apparatus for the continuous longitudinal separation of cooked tuna.

Identification number: 201330345. Country: Spain. AMFACO-CECOPESCA. See complete info

Meniño Cotón José Luis, Moreno Carbajo, Vanesa and others.

Title: Process of elaboration of dehydrated mussel lyophilized paste.

Identification Number: ES20130031484 20131009. ALFONSO GARCIA LOPEZ S.A. View complete info

Meniño Cotón José Luis, Moreno Carbajo, Vanesa and others.

Title: Process of elaboration of canning of freeze-dried mussel paste in tomato.

Identification Number: ES20130031485 20131009. ALFONSO GARCIA LOPEZ S.A. View complete info

Meniño Cotón José Luis, Moreno Carbajo, Vanesa and others.

Title: Process of elaboration of dehydrated tuna freeze-dried paste.

Identification number: ES20130031486 20131009. ALFONSO GARCIA LOPEZ S.A. View complete info

Meniño Cotón José Luis; Moreno Carbajo, Vanesa et al.

Title: Process of elaboration of canned tuna freeze-dried paste in tomato.

Identification Number: ES20130031487 20131009. ALFONSO GARCIA LOPEZ S.A. View complete info

Meniño Cotón José Luis; Others.

Title: "Freezing equipment for food products".

Identification Number. ES2552844 B1 ANFACO-CECOPESCA, TECINGAL NOROESTE, S.L. View complete info

Meniño Cotón José Luis; Others.

Title: "Freezing equipment for food products".

Identification Number. ES2570254 B1 ANFACO-CECOPESCA, TECINGAL NOROESTE, S.L. View complete info

R&D PROJECTS

TERMODIX.

Development of a digital temperature control system for industrial sterilization processes, co-funded by the Galician Agency for Innovation of the Department of Economy and Industry of the Xunta de Galicia.

INNOSABOR.

Development of a line of innovative products in the meat canning sector that increases food safety and organoleptic quality through nanotechnology and artificial intelligence. FEDER Interconecta 2013.

MUSSELTOP.

Integral Improvement of the Mussel Transformation Process.

ALISEG.

Increasing food safety in national and international markets through the development of new technologies and sustainable and innovative processes.

DEM-PRECON.

Virtualized canned food manufacturing process demonstrator using artificial intelligence and other digital technologies.

DEM-PRECON is based on the development, promotion and adoption of digital technologies that enable the stimulation of demand, through the development and validation of a demonstrator that allows to analyze the viability of the same in real environments. In this case, the demonstrator will focus on the food industry that applies thermal treatments on packaged food (canning industry) to make it more productive and incorporating the concept of food safety culture.

MUSSELPRO.

An innovative solution based on technology that optimizes and controls mussel cooking and sterilization conditions, adjusting processing times and temperature levels according to the characteristics of each batch of mussels to be processed.

-Reduction of processing times -20%.

-Reduced energy consumption per cycle -15%.

-Reduced water consumption -50%.

-Lower GHG emissions -15%.

-Higher production +20%.

FEDER

Innterconecta 2015 Pluri-Regional has been subsidized by the Center for the Development of Industrial Technology (CDTI) with the support of the Ministry of Economy and Competitiveness, and co-financed by the European Regional Development Fund (ERDF), within the Operational Program for Smart Growth ERDF 2014-2020.